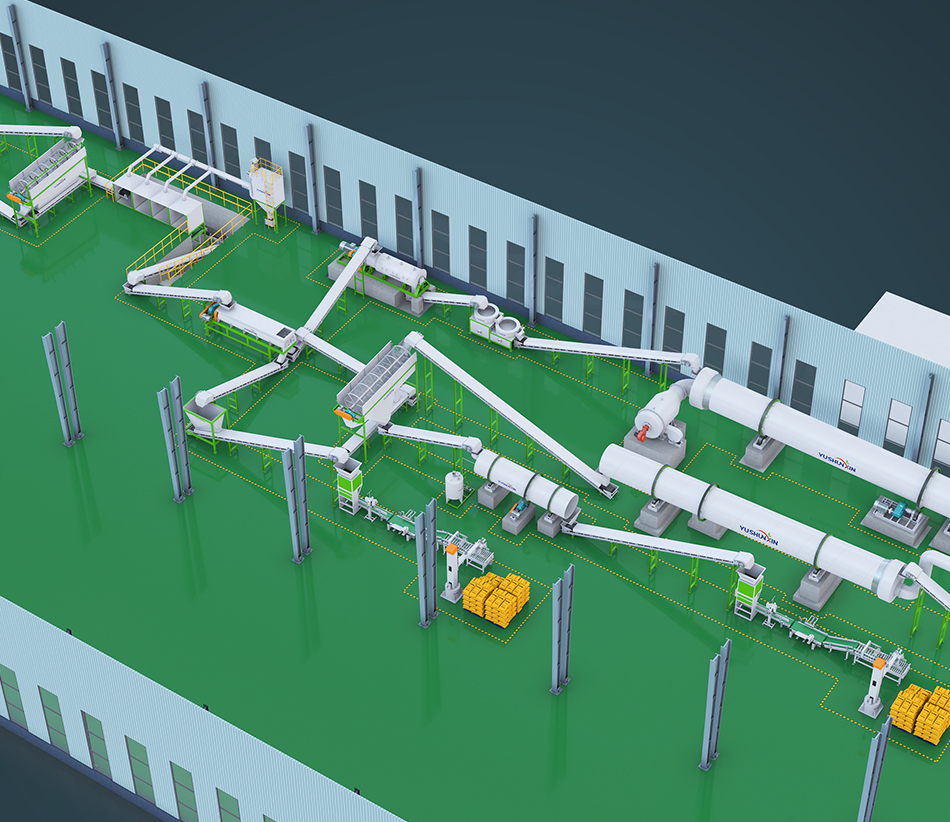

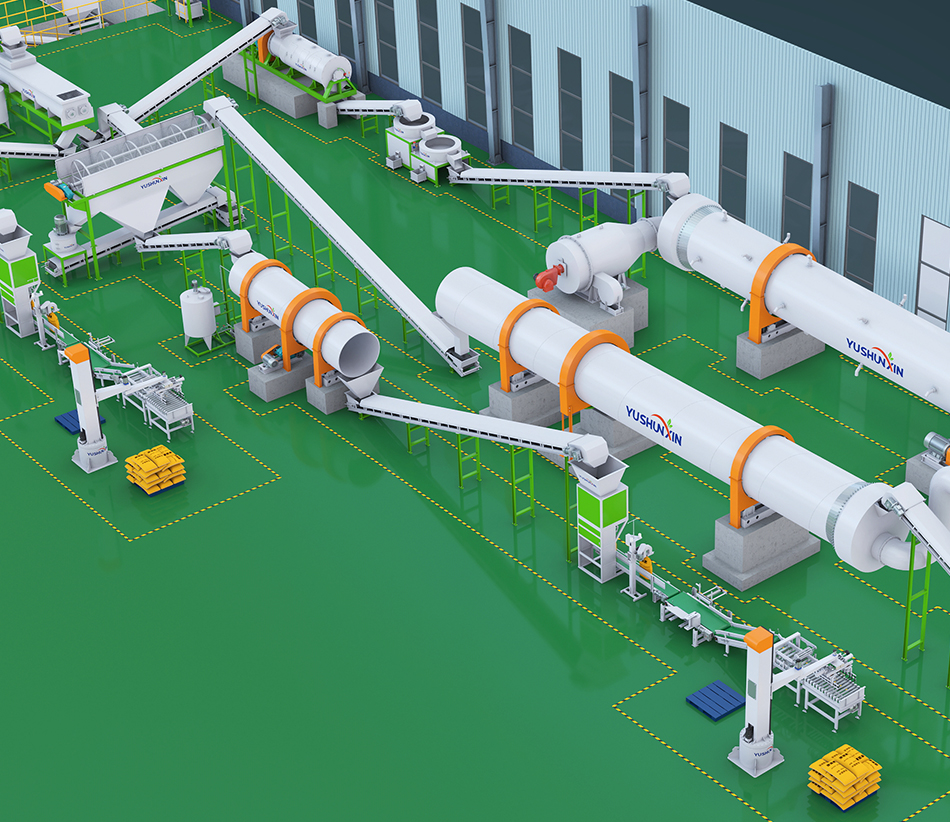

Henan Yushunxin machine co., ltd. is integrated with R&D, manufacturing, and sales, and is located in Henan province, which is the most important grain area of China. The founder of our company has been involved in the field of regeneration using agricultural waste such as straw and stalks since the 1990s, focusing on the technology and machinery manufacturing of carbonizing plant, pyrolysis plant, lithium battery recycling plant, solar panel recycling plant and so on. At the same time, we have introduced internationally advanced large and medium-sized metal processing equipment, including 10 machining centers, 3 laser cutting machines, and more than 80 types of equipment. We are a self-operated import and export enterprise in China.